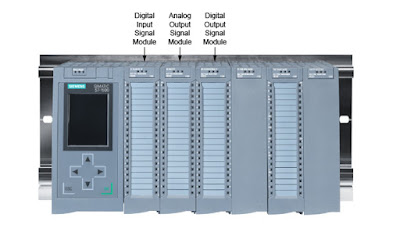

In This chapter we discuss about Siemens ( Distributed I/O , System Configuration ,PLC Tags, Monitoring Values in the CPU) devices overview.

Distributed I/O

- A PLC I/O system can include components mounted near a CPU and components dispersed throughout a facility.

- PLC I/O system components mounted remote from the CPU are referred to as distributed I/O.

- Many Siemens PLC models are designed to use SIMATIC ET 200 distributed I/O systems with network connections.

- These systems include some components designed for control cabinet mounting and other components designed for use without control cabinets.

ET 200 systems include:

- ET200S

- ET200MP

- ET200SP and ET200 ISP

- ET200M

- ET200 Pro & ET200 Pro WLAN

- ET200 eco

- ET 200 eco PN

- ET 200S is a Multi functional highly modular I/O system.

- Interface modules with a PROFINET or PROFIBUS connection and with or without an integrated CPU and are available.

- ET 200MP is a scalable I/O system used both as centralized I/O and in distributed configurations with PROFINET ET 200SP is a scalable and highly flexible distributed I/O system with a PROFIBUS or PROFINET interface module.

- Interface modules are also available with CPU functionality.

- The version of this system designed for areas subject to explosion hazards is ET 200ISP ET 200M is a modular I/O station for the control cabinet in high-density I/O channel applications.

- Interface modules are available for PROFIBUS and PROFINET ET 200pro is an especially small, extremely rugged, and high-performance I/O system.

- Interface modules are available for PROFIBUS and PROFINET An ET 200pro IWLAN version is available for wireless connection to a PROFINET 10 controller.

- Interface modules are also available with CPU functionality ET 200eco is a compact block I/0 for cabinet free installation directly on the machine and it connects via PROFIBUS.

- ET 200eco PN is a compact block I/O for cabinet free installation directly on the machine and it connects via PROFINET.

System Configuration

- Siemens SIMATIC PLC'S configuration and parameter assignment is accomplished using STEP 7 engineering software which was originally developed before TIA Portal and is now also available in TIA Portal.

- STEP 7 Professional TIA Portal works with most modular SİMATIC S7 PLC'S.

- S7-1200 PLC'S can also use STEP 7 Basic TIA Portal.

- Part of this configuration involves assigning unique identifiers to system components.

- There are various types of identifiers needed for different uses.

- For example device addresses identify programmable modules with interfaces to a network.

- A type of addressing that is critical for signal modules is I/O addressing.

- I/O addresses are assigned automatically when signal modules are added in STEP 7 and can be changed later if needed.

- The addresses of a digital signal module's inputs (I) or outputs (Q) are assigned in groups A, even if the module does not use all 8 channels.

- This gives every channel on a digital signal module a unique address that identifies the bits in the CPU's process image that store the channel statuses.

- For example, the digital input signal module shown in the accompanying graphic has 32 input channels.

- This graphic also shows the input address assignments for each channel if the module is configured as described.

- If this digital input signal module is assigned a starting byte address of 3 the channels will be assigned the input addresses shown below and will control the corresponding input status bits in the process image.

- Because an analog signal module has a resolution of up to 16 bits, 16 bits are required in the CPU's process image to store an analog input or output channel value.

- As an analog signal module is added in STEP 7, I/O channels are automatically assigned addresses.

- If the starting byte address of this analog input signal module is 256 the analog channel will use the following input bytes.

- For example if an S7-1500 8 channel analog input signal module is assigned input byte 256 as the starting address the channels will use the input bytes shown in the accompanying graphic.

PLC Tags

- STEP 7 allows the use of symbolic names, referred to as tags, associated with memory addresses.

- PLC tags are stored in the CPU's PLC tag table.

- Tag names can contain letters, numbers, and some special characters, and each tag name must be unique for a CPU.

- Use of tags helps when debugging a program or troubleshooting a system.

- The accompanying graphic shows an example of a PLC program network with the following tags assigned:

Start, Stop, and Motor

- Tags are shown in quotation marks in the STEP 7 (TIA Portal) program editor.

- Instruction operands can also be displayed. Absolute operands (such as 11.0,11.1, and Q3.0 in the accompanying graphic) are preceded by %.

- Absolute operands are available for use in any program block.

- Operands preceded by # are assigned to a specific program block

Monitoring Values in the CPU

- STEP 7 (TIA Portal) software provides a variety of ways to monitor system operation if the programming device is connected to a CPU.

- This is useful for debugging a program or troubleshooting a system.

- For example the accompanying graphic shows how a program network appears while being monitored in the STEP 7 TIA Portal program editor with the push buttons in their normal state and the motor stopped.

- Note that the Start and Motor normally open contact instructions are shown in blue to indicate that they are open.

- The Motor output coil instruction is also shown in blue to indicate that it is off.

- The accompanying graphic shows how that program network appears in the STEP 7 (TIA Portal) program editor while the start push button is being pressed.

- Note that the three normally open contact instructions are shown in green to indicate that they are closed and the motor output coil instruction is also shown in green to indicate that it is on.

- Finally the accompanying graphic shows how that program network appears in the STEP 7 TIA Portal program editor after the start push button is released.

- Note that the Start normally open contact instruction is once again shown in blue to indicate that it is open.

SIEMENS PLC Class for Beginners

No comments:

Post a Comment